Laser Scanners: The automotive industry is one of the largest markets for metrology equipment. In particular, hand-held laser scanner devices are used extensively in the automotive field to create accurate models and prototypes of new car designs and to update existing models. As the automotive market continues to evolve, so you must use the manufacturing techniques to produce exterior parts. Suppliers must continuously innovate in order to remain competitive, and upgrades to technology and production methodology are crucial in this effort.

When implementing, it’s common for engineers to rely heavily on automated hardware like the laser scanner. These handy devices have become standard tools in industrial environments, and can be found in machining, packaging, and prototyping. They’ve been crucial in advancing the manufacturing industry.

However, when engineers take over, there may be a few mistakes that occur that will cause issues with the laser scanner.

Keep a stable platform while using Laser Scanners

Keeping a stable platform is very important for the development of laser technology, so what problems do we need to pay attention to it?

- The stability of the laser platform should be ensured during the use of laser equipment on the platform, and it should be checked and adjusted during the commissioning of the laser system.

- It is necessary to check the stability of the laser platform during the use of laser equipment and to maintain it. The design and installation of the laser systems should be based on the actual needs of the user, and the design of the laser platform should be reasonable

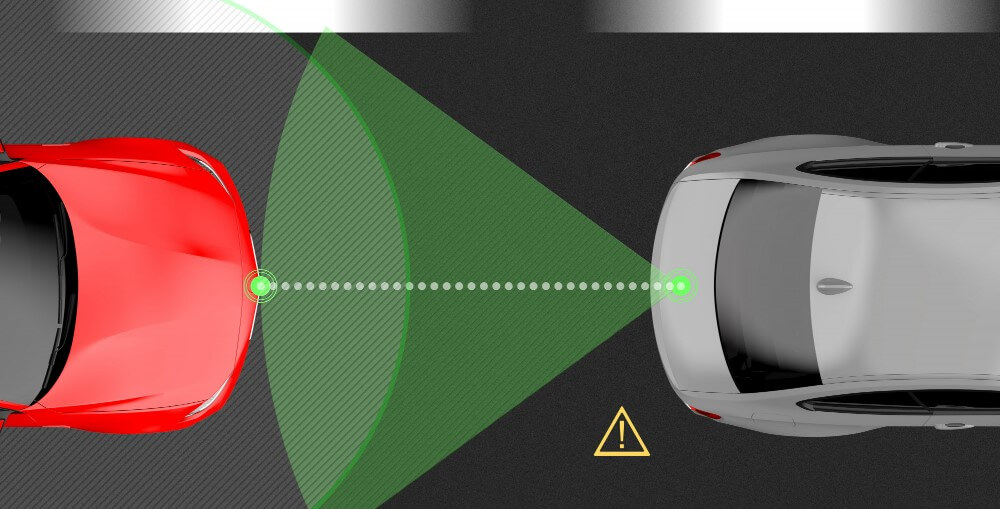

Use camera calibration

Laser Technology is a new way of taking pictures. It works by bouncing a laser off the subject you are trying to photograph and measuring the time it takes for the light to bounce back. It’s a lot like radar, but it allows you to get a 3D image of the subject you are photographing. The images it produces are very accurate, but they are also very delicate. The slightest movement changes the quality of the photos. Sometimes you can use a tripod to stabilize the camera, but sometimes you can’t. In those cases, camera calibration is the best option.

Use reliable software

The use of reliable software is required to correctly read the captured image. The software should be able to identify the license plate number, state, and year. It is also important for the software to be able to determine if the plate is a front plate or a rear plate.

Conclusion

If you are looking to hire a laser scanners service, be sure to ask about their scanning equipment, experience, methodology, and processes. This short interview will help you determine if they have the capability to handle your project. With Red Sensors, you can rest assured that all of our professionals are trained and certified. We have the relevant industry experience to help you achieve your goals!